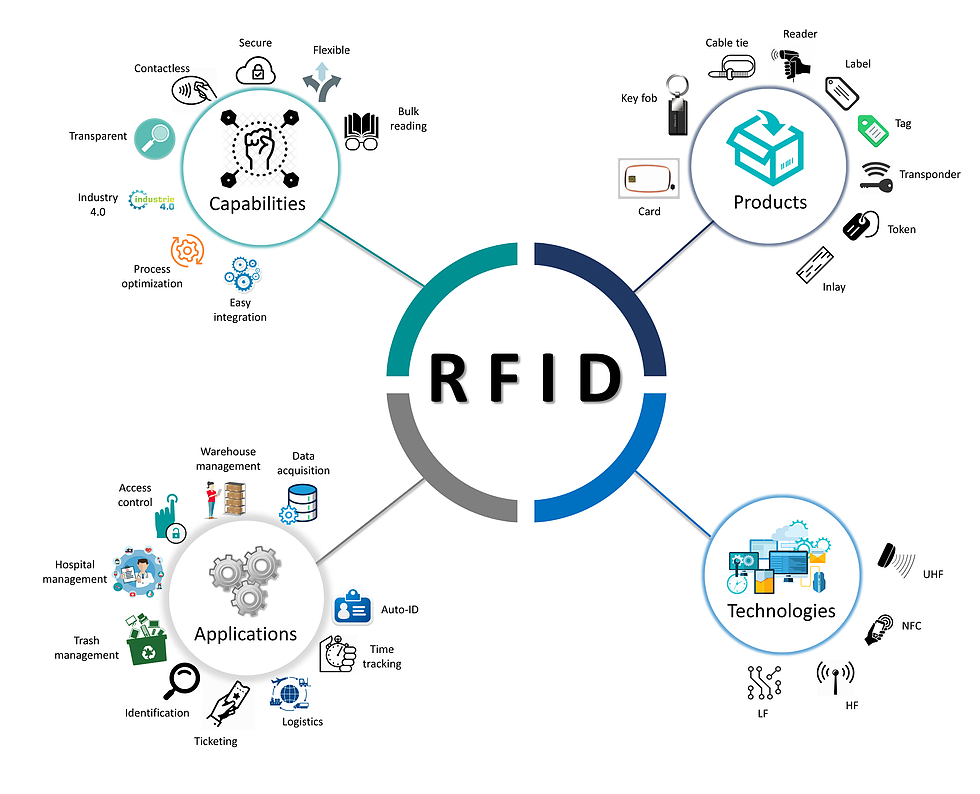

The World of RFID

The Path to Your RFID Solutions

Publications

"Soft housing -

Smart tagging"

"Cable tie transponder with housing made of soft material expand the RFID application spectrum with new options."

"Full UHF performance

with minimum distance to

metal through innovative

antenna design!"

"Wideband antenna design and specially tuned antennas should provide a solution for flat and robust on-metal tags."

"Now the card speaks!"

"The next generation of the ISO card: Acoustic cards as an alternative to NFC can increase the level of security in mobile payment applications."

Contact us

Deutsch

Deutsch